Top Secret Belongs in the Past

The OPENNEXT project conducts research into how the ideas of open source can also be established in hardware product development

On the one hand, we have research and development departments working in the strictest secrecy. On the other, digital platforms where blueprints for drones, robots, and telescopes for use in astronomy are freely available to anyone. "We can observe that the ideas of open source software, in other words its free use, modification, and further development by third parties, are also attracting a growing following in hardware development," says Robert Mies, research associate in the Chair of Quality Science at TU Berlin. "At the same time, we can see that adapting this open source approach to hardware is not without difficulties as it involves more than just depositing a code on an open platform." In fact, as Mies goes on to say, you need a place where something can be replicated. You need tools and materials, and people who can read construction plans and operate machines, as well as understandable documentation of the entire manufacturing process.

It was these differences between open source software and open source hardware that provided the initial impetus for the OPENNEXT project at the Chair of Quality Science under the leadership of Professor Dr.-Ing. Roland Jochem. The project is funded as part of the EU Horizon 2020 program. Project managers are Robert Mies and Mehara Hassan, who is also responsible for the Chair of Quality Science's research within the project. OPENNEXT is a consortium of 19 European partners from science and industry as well as non-profit organizations, platform operators, and open workshops, the so-called makerspaces.

Avoiding expensive and unwanted developments

The project examines how the ideas of open source can also be established in hardware product development. The goal is to enable new approaches to product development in selected areas, such as furniture production, environmentally friendly mobility, and electronic consumer goods, between small and medium-sized enterprises and startups on the one hand and the makerspace community and customers on the other, and to enable these parties to network with each other. The old principle of closed innovation environments is to make way for public accessibility, the further development and dissemination of manufacturing processes, and the reparability of products. This is connected with a very important fundamental concept of open source: the goal of preventing innovations becoming lost when a company ceases to exist and avoiding expensive and unwanted developments.

The multifunctionality of a Swiss Army knife

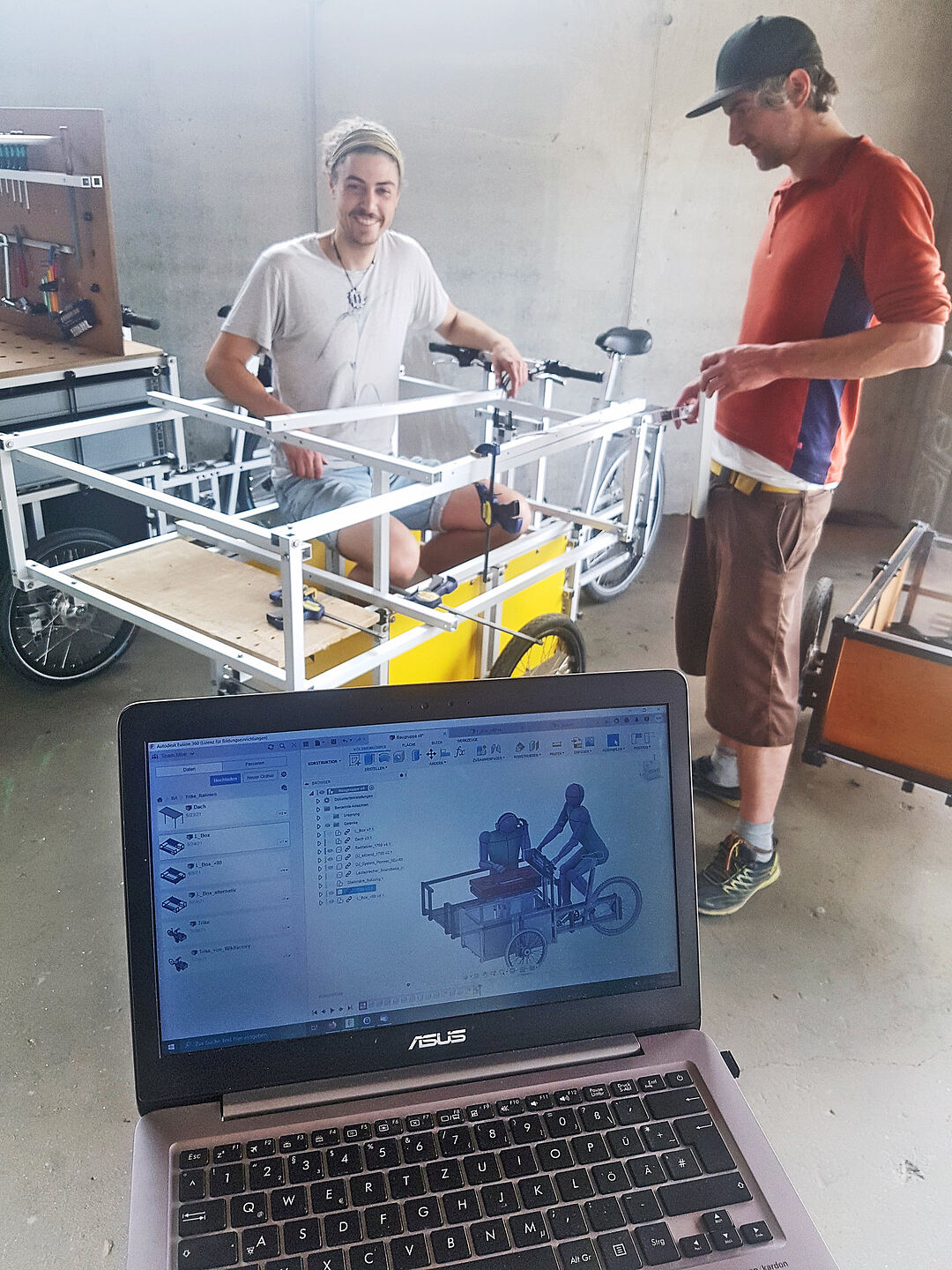

The first praxis phase of the OPENNEXT project, which has now been completed, worked together with six European medium-sized enterprises and startups with experience of open source to examine how this has become established in their companies, as part of their DNA as it were, and to analyze the infrastructure required. For example, OPENNEXT helped a Danish startup which manufactures office furniture under the slogan “No waste, no storage, no nonsense” to extend its on-demand production to create an approach to product design that involves the customer from the outset. The company then makes this process accessible for everyone on a digital platform and also invites other startups, makerspaces, and members of the public to get actively involved, explains Robert Mies. Then there was the Hamburg-based cargo bike manufacturer which OPENNEXT put in contact with open source actors such as students and a local makerspace. The company had established no previous contact to any of these groups and would have otherwise found it difficult to do so. This networking resulted in a new product idea: a cargo bike with the multifunctionality of a Swiss Army knife. Different superstructures enable different functions, transforming a normal cargo bike into something special. It can assume many forms such as a food bike, a medical bike, a mobile open workshop or even a DJ bike! These functional modules are constructed open source and can be transformed, modified, and further developed for other functions as needed.

One of the most important outcomes of the first phase is that it enabled researchers to develop an understanding of how collaborative use of open source hardware between businesses, makerspaces, and customers works, as well as the infrastructure required to support this process. With regard to infrastructure, it is important to provide shared meeting places for creative exchange and workshops in addition to digital machines for prototyping and collaboration software tools.

Risky and unsustainable

There are a number of reasons why SMEs and startups are becoming receptive to open source hardware development in the first place. One of these, according to Robert Mies, is the growing community of people and businesses who believe that a closed approach to product development is risky, expensive, and non-sustainable – particularly as it allows customers little input in the development process. Consequently, companies fail to respond to the needs of their customers. A good example of this is the non-compatibility of different manufacturers' charging cables for laptops and smartphones, which resulted over many years in inconvenience for customers, as well as expense and unnecessary use of resources. The very opposite of sustainable production! The open source hardware movement, by contrast, is driven by ideals such as the free exchange of ideas, mutual help, the fun to be had in tinkering together, and the sustainability resulting from the repairability of products. Companies also see open source as an opportunity to build closer relations with their customers and staff by specifically seeking out and supporting transparent exchange. They see this as a way to achieve stability for their business models. A third reason, according to Robert Mies, is that open source enables other ideas to be introduced into the development process, which would otherwise not be possible in a closed environment, as the need to follow regulations and specifications as well as in some cases the career interests of the engineers themselves can suppress creativity.

Science as a catalyst

The second phase of the project began in fall 2021 and involves working with 12 SMEs looking to introduce open source as a new – and profitable–corporate strategy, using a specific product idea to develop concepts for establishing open source in their companies. "At OPENNEXT we see ourselves as a catalyst," says Robert Mies. "Our research seeks to evaluate the companies using a maturity model. This model makes it possible to assess the companies' capability to work with communities when developing open source hardware as well as to derive strategic measures." Sybille Nitsche

Author: Sybille Nitsche