Project summary

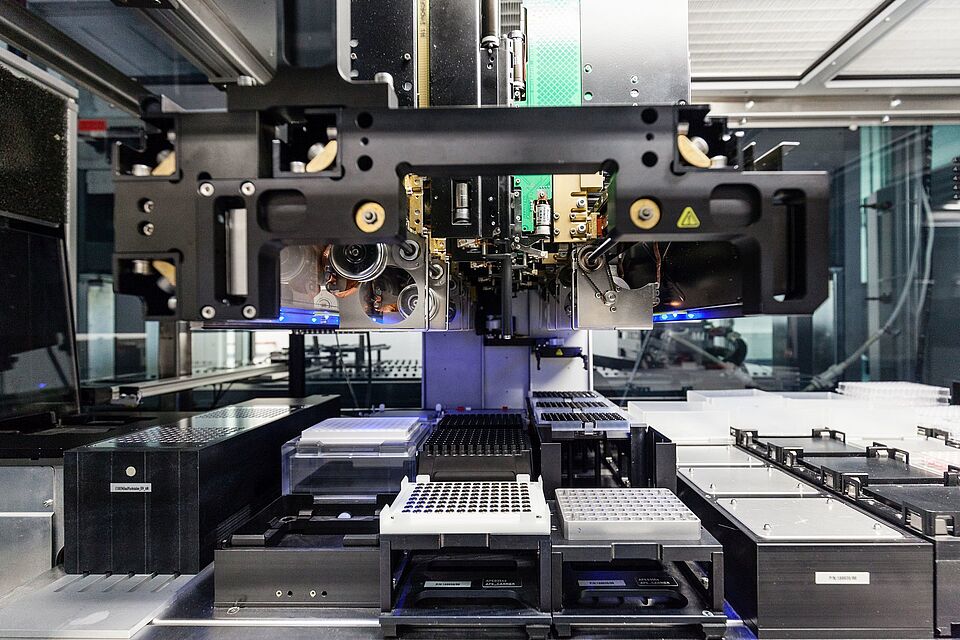

The aim of the DEEPWEP-Project is the development of a miniature multi-bioreactor system for the purpose of speeding up bioprocess development. The common approach of developing novel bioprocesses starts at lab-scale. In the beginning, screening experiments are conducted to find a suitable production strain for a certain target product. For this purpose, a high number of parallelized culture vessels with small volumes (usually microtiter plates) are used to gather enough data that legitimize a decision for a production strain. Once the decision has been made, the production strain is gradually transferred to cultivation vessels with higher volumes (shake flasks, mini-bioreactors, bench-top bioreactors, pilot-scale bioreactors, production-scale bioreactors) to further optimize cultivation conditions until finally, production scale is reached. To effectively conduct this scale-up, small-scale cultivation vessels should be able to mimic cultivation conditions of large-scale cultivation vessels. By this means, data of small-scale experiments would allow to predict process behavior of large-scale. However, due to variations in reactor geometries and process dimensions, different process characteristics (oxygen transfer rates, volumetric energy input, shear stress, mixing time, gas holdup, etc.) prevail upon different process scales. Several miniature multi-bioreactor systems have been developed to address this issue. Nonetheless, it is still not possible to entirely mimic large-scale conditions in small scale reactors which makes the development of bioprocesses a time-consuming task. This project follows a new approach by developing a non-stirred multi-bioreactor system and thus advances issues with commonly used stirred multi-bioreactors in small-scale.

The DEEPWEP-Project is funded by the Federal Ministry of Education and Research under the “National Research Strategy Bioeconomy 2030” as part of the ideas contest “New products for Bioeconomy”. As a deeper funding goal, Germany shall evolve a leading role for research and innovation in the field of bioeconomy. By developing a bioreactor system which can speed up bioprocess development time, this goal can be supported. A time reduction for process development ultimately leads to lower investment and production costs, thereby opens the market towards a broader range of competitors and increases innovation.

In the first project phase (December 2020 – September 2021) a market analysis is conducted to assess the market potential for the novel multi-bioreactor system. Additionally, a consortium of project partners and economic experts is formed to further advance a development plan for the product idea and a business concept. This development plan is realized and put into action in the second project phase.

If you are interested in this project, please do not hesitate to contact us.

© TU Berlin/PR/Felix Noak

© TU Berlin/PR/Felix Noak

© Dominic Simon

© Dominic Simon

© TU Berlin/BVT/S.Hans

© TU Berlin/BVT/S.Hans

© Philipp Arnoldt

© Philipp Arnoldt